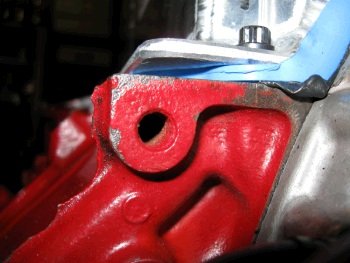

Starting over with the photos now but with captions. Some

oil just under the front of the intake manifold. Possibly an

RTV leak. |

The interior of the motor is squeaky clean. Love the

frequent oil changes. The intake runners all have some oil

stains and I don't know exactly where that's coming from right

now. |

Intake runners with the oil stains. |

The other side. |

Spark plugs look to me like the tune up was very very good. |

Just another view. |

Prior to removing the valve train. |

The valve tips do not show any witness marks. No wear at all? |

Everything is organized nicely in my valve-train organizer tray. |

The oil pump drive gear and the cam gear had only slight wear.

(normal). |

The cam lobes all look normal with slight wear. |

No oil gunk on the chambers. No signs of oil ring blow by. |

A view of all the piston tops. This all looks a bit cleaner

than most motors I've seen. |

The other bank. |

One rod bearing out of 8 had some dirt stains. This is #1

but the photo does not show it very well. |

All the rod bearings look quite nice, (except #1) |

Piston skirt rocking in the bore makes that mark on the cylinder

wall. |

Photo sort of out of order but here is the bottom end right after

taking off the oil pan. |

Crank out and main bearing are all like new except the thrust. |

The thrust bearing has one dirt line from debris. |

|

The crank is at the

balance shop waiting for balance, (needs heavy metal

probably). The block is going to get a plateau hone to be

ready for the new pistons. |

|

Finally the balance is completed. I delayed for quite a

while too due to wedding plans and all that jazz. So here

are the new pistons on the oid Compstar rods. |

Another view. |

Sorry there are not more photos...I started the day with no

batteries for the camera...I did not want to delay so I put the

crank in and did the ring gap..then went to the store. |

Speed Pro Hell-Fire. The top is at .026" and so is the

2nd ring, as per Speed Pro suggestion. The top ring is very

stiff, (hard). The 2nd ring is quite soft. |

Started out with ACL standard H-series bearings and that gave

.003" rod bearing clearance. Then went to Clevite

H-series standard and have .0025" clearance. The

Clevites are what I used. |

New camera allows me to get macro photos now. The bore

hone. It is a plateau hone. |

Nice photo of the JE piston in the hole. |

Not an official deck-height measurment yet but just an eyball.

It is in the hole some .005" |

All pistons in except #7. |

All pistons in. |

Posing. |

More posing. |

And more posing. |

The bottom end. |

Final torque of rod bolts, (75ft-lb), .018" to .020" rod

side clearance. |

Nice view of the JE pistons |

Timing set install, TDC find. |

Piston is .002" in the hole. |

Cam is dead nuts on at 112deg intake lobe center. |

Another view of degree check set up. |

Old timing cover on and new seals to be installed. |

New Titan Gerotor oil pump. Stud nut at 65ft-lb with moly. |

Fitting of windage tray. |

Rod clearance check. |

Have to bend the tray for the Stef's pan. |

Dipstick tube bends a little around the main cap nut. |

Pan does not fit. |

Mistake in manufacture. |

Another pan off the shelf and it does fit. |

Trial fitting prior to oil pan gasket. Crank clearance

check. |

Some spots on the oil pan need to be ground for crank clearance. |

Fit-check looks good. |

One of the last motors to be assembled in my shop/kitchen.

Will be married soon and my shop will become a home. Engine

building will be outside on the porch or new garage. |

New ARP 12pt head bolts. Super clean and with ARP thread

sealant. |

FelPro head gasket on and a good look at the cylinders and

pistons.

|

One head on and here is a final look at the pistons.. |

Another view. |

Head on and ARP head bolts at 65ft-lb |

The Jesel shaft rocker stands will be installed over these

.100" shims. |

Taking a break here. The Jesel shaft stand bolts are being

soaked in cleaning solution so that I can put sealant on the threads

to keep oil from being sucked into the intake runner. |

Jesel rocker stands are on and the bolts have ARP thread sealant. |

The intake manifold intake runners were cleaned with brakclean so

that we can see if oil is getting in the intake in the future. |

The manifold looks to sit pretty well on the gasket. This is

just a mock-up to see if I can spot problems. |

Another view. |

This pan is hard to fit. I did quite a lot

"tweaking" for lack of a better word. |

Here I'm just putting RTV on the gasket/block surface and not on

the pan/gasket surface so that the pan can be removed. |

More views of the oil pan. |

Now with 4 quarts of Shell Rotella 30 weight. |

The Titan gerotor oil pump is spinning nicely with my drill at

2500rpm. 60psig. |

Intake manifold on and motor wrapped and ready for shipping. |