|

Maybe you can see the Lunati crankshaft and Stef's oil pan and Titan

gerotor oil pump in this photo. Also the valve covers are the

chromed version of the Chevy ProForms. The one item I don't have yet

is the billet Oliver connecting rods. After those arrive then

the crankshaft will be balanced.

|

I picked up the fully machined block from McKeown Motorsports

Engineering a few days ago, (August 7th). Mark McKeown is a

Jeg's Engine Master Finalist and has been very helpful to me with my

new business. Mark's guys gave the block a quick coat of black

paint over which I will add a layer of PRO-15 (Red).

|

|

Piston weight is 525g which is heavy but

this is a sturdy piston for forced induction. A flat top Mahle

is about 410g for comparison.

|

This is my new area to weigh parts, (in

my office). No greasy parts allowed.

|

|

Block is not fully cleaned yet. It gets one more cleaning

after I file-fit the piston rings. Here is a fresh layer of

red paint.

|

I switched blocks on the project. I'm using a fresh fully

machined block from Golen. (It was cleaner on the outside for good

paint). I hate how the camera makes the red look purple.

|

|

Rings are filed. (.020" top and .024" 2nd ring).

|

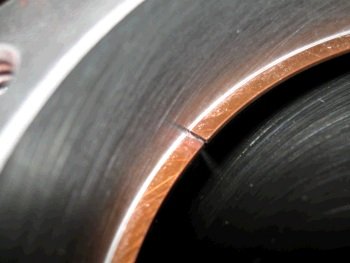

Here is a close up of a top ring with a bit of flash shine to mess

up the photo. The rings are pretty far down from the top of

the piston and so that is why the top ring gets a tight gap,

(.020").

|

|

And the 2nd ring, (it is softer since it does not get the heat of

combustion).

|

Proof that I have installed the oil filter oil gallery plug.

|

|

A beautiful Callies USA made crankshaft.

|

Custom Ross piston and Oliver billet rod, (5.850").

|

|

A nice view of the ring package. The rings are quite thin for

minimum drag but that does compromise a little oil

consumption. But Hot Rods are always adventures in compromise.

|

Oliver rod bolts are stretched to .053" which is about 80ft-lb.

|

|

Nice view. The pistons are at exactly .000" deck-height.

|

Another nice view.

|

|

Trust me, the paint is really red. My camera is in

"auto" mode and I would not know how to adjust it in

manual mode.

|

Billet timing set. Crank sprocket installed at "0".

|

|

Cam degreed to within 1 deg. of the cam card. This is a

mechanical roller cam shaft from Advanced Induction.

|

Now getting the bottom end buttoned up. The Titan gerotor oil

pump goes on.

|

|

This is almost the true color of the red paint. A Kennedy

50cent piece plugs the timing cover.

|

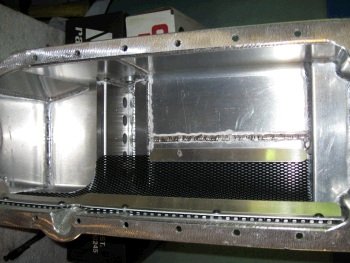

Clean up and test fit the Stef's oil pan.

|

|

Trimmed to fit stock LT1 windage tray.

|

Windage tray needs to have the ends bent down to clear the Stef's

oil pan and also I push up in the center of the tray to help clear

the rods.

|

|

Test fit of pan without gasket.

|

About one hour later the pan is on and RTV is on all surfaces of the

pan gasket, (top and bottom).

|

|

Fuzzy photo of the Cometic head gasket... LT1, .040" thick.

|

TFS heads CNC ported by Advanced Induction. Test fit for

pushrod length-check.

|

|

Looking here at the fine machined Xceldyne retainers.

|

Pushrod needs to be 7.900" long and thankfully I have a set on

the shelf.

|

|

ARP 12pt head bolts cleaned and coated with ARP thread sealant.

|

Heads on and Jesel shaft rockers on. Now doing the engine oil

pre-lube.

|

|

The pump makes 50psig at 2500 drill rpm.

|

No leaks and all rockers have oil from the pushrods. Now

draining oil...(the motor need to be oil free for shipping).

|

|

I wish that the camera would not make the paint look

pink/purple. It really is red.

|

Test fit of the AI ported intake manifold. Perfect fit.

|

|

Nice pose.

|

Proform valve covers.

|

|

Another view.

|

The ATI super damper stays off so that it will not get dinged during

shipping.

|