|

What an awesome shop! This engine is an already built

LT1-396.

|

Motor arrives in Maryland without a scratch. We'll look deeper

into the motor and see what can be left alone and what might need an

upgrade.

|

|

An Ellwein/Stef's oil pan is always a good idea.

|

Since we have a 3.875" stroke motor I think a pan with stroker

notches might be a good idea.

|

|

The Stef's pan is build to my specification with an oil level sensor

bung and front notch and room to fit a Titan gerotor oil pump.

|

Check out that notch in the front. That is required when the

motor lives in an Impala SS due to the steering center-link.

|

|

|

|

|

quite a bit of cooked on oil but clean otherwise.

|

|

|

|

GM LT4 heads, (unported)

|

|

Looks like SRP -16cc D-dish pistons

|

Bone stock main caps.

|

|

|

A very nice Callies USA crankshaft.

|

|

Connecting rods of unknown brand. They look a bit like Oliver

billet, (but they are not).

|

Main bearings are in bad shape. All worn down to copper.

The rod bearings were all out of shape too.

|

|

3.875" stroke.

|

The cylinder heads

will be shipped off to Advanced Induction.

The block will be set aside and we have a fresh block on order from

Chad at Golen Engines. |

|

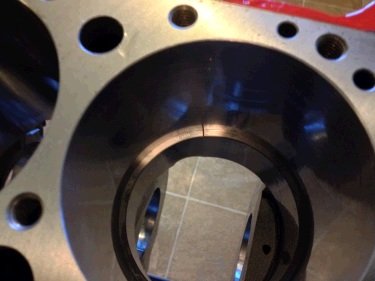

Freshly machined block

|

Main caps a little rusty on the non-machine surfaces. All will

receive a buff and a good POR-15 paint job

|

|

Here is the Callies crankshaft on the balance machine.

|

Advanced Induction ported LT4 intake manifold. I like how they

remove the core plugs so that they can clean it and I can verify that

it is in fact clean.

|

|

|

Powder coated Red

|

|

|

The block is a bit "more" red than the GM LT4 red but a

pretty good match.

|

|

|

Custom piston from Diamond. Notice the pin boss area is

polished.

Piston is 406.5g, Pin 119.4g, rings 34.8g, wire lock 2.7g

|

|

I weigh the parts individually and as a unit.

|

563.4g added up individually and 563.0 as a unit.

|

|

While the Crankshaft is at the balance shop I will clean the block,

add freeze plugs, install oil galley plugs, install cam bearings and

file fit the piston rings.

|

Here the block is posing with the freshly installed freeze plugs.

|

|

Then cam bearings

|

Notice that the oil galley plugs are threaded.

|

|

This is the oil galley plug that goes under the rear main cap.

|

One method I like to use to measure piston to cylinder wall clearance

is via feeler gauge. Here I have .004" and the recommended

clearance from Diamond is .0045"

|

|

Ready for piston ring file fitting.

|

Top ring at .024" (just in case the motor gets a small hit of

nitrous in the future.).

|

|

2nd ring at .0020". (Mahle and Total Seal both recommend the 2nd

ring gap to be smaller than the 1st ring gap. This is a change

from the past.

|

The pistons are "L" and "R". This helps me

organize and acts as a 2nd check to the proper orientation.

|

|

|

All rods and pistons assembled, (except rod #4 which is at the machine

shop).

|

|

|

Picking up the crankshaft tomorrow. Soon you will see final

assembly.

|

|

Main bearing clearance check. Mostly a mix of .001 under and

standard in order to make the bearing clearance slightly tight.

.0017" to .0020"

|

|

|

|

Notice that I enlarged the oil hole in the bearing to match the oil

hole in the block.

|

|

Thrust is .008"

|

Rod bearing clearances set with a mix of .001 and standard bearing

half shells. Generally .017" to .0022"

|

|

This is a 4.035" piston. I don't have a tapered ring

compressor for 4.035" but I do have this super duper tool and

it's working quite well.

|

Pistons are .003" out of the hole

|

|

|

|

|

Advanced Induction camshaft.

|

Single roller timing set from Cloyes set on "0"

|

|

1st check 103.5 degree intake center. 2nd check 104 degree

intake center. This is with crank sprocket on the "0"

position.

|

Titan gerotor oil pump installed. Modified stock windage tray

installed.

|

|

All rod bolts torqued to 65 ft-lb. Rod side clearance is .018"

|

Last look at the chambers of the Ai CNC ported LT4 cylinder heads.

|

|

|

Very nicely stress relieved and finished valve springs.

|

|

ARP head bolts cleaned and loaded with thread sealant.

|

|

|

Cometic MLS head gasket.

|

|

|

Crower shaft rocker sits right on the valve tip. Nicely

centered.

|

Pushrod length check. 7.2"

|

|

You can just make out the mark. Right in the center of the

valve.

|

New oil pan from Stef's. The other one had to be sent back for

repair. Then it was lost by UPS. (1st time UPS messed up a

shipment for me). Now this new one has a billet rail.

|

|

....And we ordered it with an 1/8" NPT bung for oil temp sender.

|

Final view of the bottom end. I only used RTV on the ends of the

oil pan gasket.

|

|

The firm billet pan rail compresses the oil pan gasket very nicely.

|

I am hoping that the oil pan does not seep oil when the motor is

installed and running. It looks to be a very good seal by eye

and feel. The pan fits very well and there are no crank or rod

bolt clearance issues.

|

|

One head had to go to the machine shop to have the valve cover

hold-down bolt boss fixed.

|

Now the head is reinstalled and ready for the shaft rockers.

|

|

Shaft rockers on.

|

LT4 head gasket on and ready for intake manifold.

|

|

Before the intake manifold goes on I will do an oil system test.

|

2500rpm drill gives 58psig with 30W oil.

|

|

|

All lifters pumped up and sending oil up the pushrod to the rocker.

|

|

GM LT4 intake manifold gasket #1236777

|

A nice thick bead of Right Stuff RTV

|

|

|

|

|

Old (non-LT1) thermostat on the left and new Hypertec 160T-stat on the

right.

|

I drill holes in the T-stat if the motor has an electric water

pump. That allows for bleeding of the coolant system without

running the engine.

|

|

Taped up and ready for shipping.

|

|

|

Extra long tranny dowel pin transferred from old block to new block

|

|

|

|

Wrapped up tightly and ready for R+L

Carriers

|

|

|

|

|

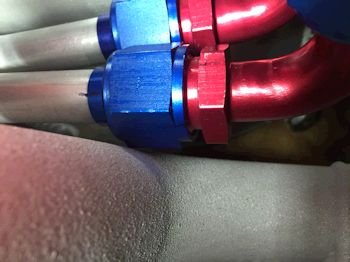

Nice wire loom and oil line set up.

|

Notice the Meziere starter and looms

|

|

Stainless oil fittings.

|

Custom oil line support

|

|

|

|

|

|

Very clean and well made remote oil cooler

lines.

|