|

Tear-down shows a clean intake manifold

|

|

|

Brian has great success with the EFI Connection 24x system.

|

This is a blower motor so Brian used Cometic MLS head gaskets.

He coated them with copper spray which did not seem to hurt a thing.

|

|

We are looking for evidence of oil consumption. The motor ran

great and made good power but used oil.

|

This is a very well made motor. Good

design. Good machining. Good assembly.

|

|

|

|

|

1st rod removed. The Callies crankshaft looks brand new.

|

|

|

Eagle splayed main caps in the 3 center positions.

|

|

|

All rods and pistons are in very good shape.

|

|

|

Just a note about the cam pin. When installing the EFI connection cam

sensor, it needs to be shortened a bit.

|

I had the same timing chain rub marks on a recent customer's motor.

|

|

Could not get 2 of 3 cam bolts off. I ended up grinding

the heads of the bolts off.

|

This is a photo of the main bearings. Brian used stock main

bearings and they seemed to work quite well.

|

|

|

|

|

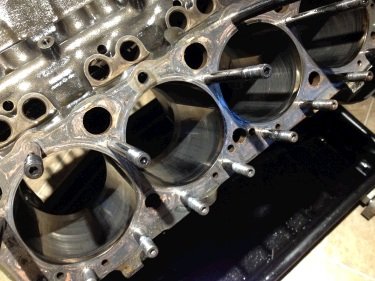

Right now the conclusion is that this shiny area of the cylinder

walls is from fuel wash.

|

Another photo of rods and rod bearings.

|

|

Fuel wash?

|

Next: Heads and

block go to the machine shop.

Valve springs will be checked and re-used if good. Heads will be

cleaned and receive new valve stem seals. Block will be

honed. ARP/Milodon studs will be added to mains and align hone

if needed.

|

|

Callies crank rod journals at 2.0990" and Mains at 2.4480"

|

Clearance at .003" using standard size Clevite H

|

|

|

|

|

.0027"/.0028"/.0025"/.0028"/.0030"

(1,2,3,4,5)

|

|

|

Photo verification that the oil galley plug is installed.

|

I widened the oil hole in the block slightly to align with the Clevite

H bearing.

|

|

CMD #3 lube on cam lobes.

|

Crank installed and thrust at .008"

|

|

Bores thoroughly cleaned.

|

All pistons checked to be .006" piston to bore clearance.

|

|

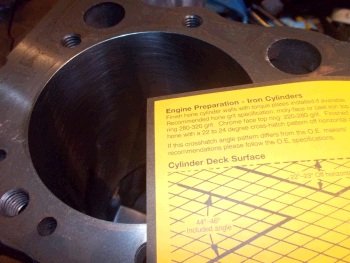

The block was honed to Total Seals spec.

|

Ring filing. This is my 4.035" piston used as squaring

tool.

|

|

Top ring at .030", 2nd ring at .025"

|

Total seal gapless top ring set.

|

|

I gapped the "gapless" rings too to .030"

|

Rod bearing clearance check. Rod bolt at .005"

stretch.

|

|

Standard size Clevite HN bearings, (.0022")

|

#1 piston in the hole.

|

|

I made sure to clean the pistons, especially in the ring groves.

|

Also re-greased the rod bolts.

|

|

All 8 pistons installed.

|

Torquing rod bolts, (75ft-lb)(.005")

|

|

Rod side clearance is .020"

|

|

|

Fitting up a stock windage tray.

|

I bent the sides of the windage tray in order for the oil pan to

clear.

|

|

Milodon 10552 high pressure oil pump. The pickup had to be

slightly messaged to fit in the Moroso oil pan.

|

Piston is 0.000" in/out of the hole.

|

|

Cam degree check. ICL at 109deg right on with the cam card.

|

I was able to ditch the EFI connection cam bolts and use stock cam

bolts.

|

|

|

|

|

I have a head bolt thread cleaning tool and put it to good use.

|

Head studs cleaned with soap and water.

|

|

Cometic says not to use copper spray but....

|

....the Jeg's Engine Master Lennart Bergqvist uses this technique.

I sprayed in-between all three layers.

|

|

My method to seal the head studs is to use Right Stuff RTV

|

Heads on and torqued.

|

|

|

These are very good looking valve springs. I took a photo just

for my enjoyment.

|

|

Swapping over to 7/16" rocker studs from 3/8"

|

These are non self aligning rockers. We are using Isky

adjustable pushrod guide plates.

|

|

|

|

|

|

|

|

Here is a good view of the ISKY guide plates.

|

It may not look like it but the rocker tips are well centered.

|

|

One last view of the bottom end.

|

|

|

RTV on the oil pan gasket at just the front and rear ends.

|

Old crank seal hanging and new in the box.

|

|

Oil pan on.

|

Photo of the nifty Callies crank stud.

|

|

|

|

|

Oil pressure check. All good.

|

Last view of the intake valley.

|

|

Intake manifold on and posing for photos.

|

|