|

LT1 for 3rd gen Fbody

|

The heads look good.

|

|

|

F-body heads

|

|

|

|

|

Unknown plastic in #5 hole

|

?

|

|

|

#1 piston

|

|

The area on the head that corresponds to where #1 piston has the

damage

|

Nice GMPP timing set

|

|

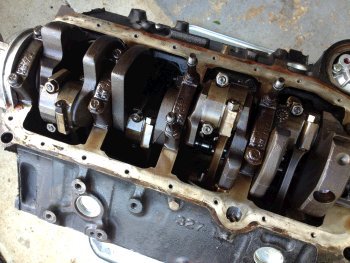

2-bolt mains

|

Oil pump looks pretty good.

|

|

|

Oil pan looks good.

|

|

#1 piston, (sorry for out of focus)

|

#3 piston, (#7 looks the same way)

|

|

Block ready for trip to machine shop. 4-bolt main caps will

be installed.

|

Received block back from machine shop and then clearanced for

stroke and washed.

|

|

Cam bearings installed.

|

|

|

Now painted with POR15 engine black

|

|

|

|

Oil gallery plug installed and camera gives me proof.

|

|

Main cap bearing clearance check

|

All mains using standard size bearing

shells except #1 which uses a mix of .001 and std

|

|

|

|

|

|

Rear main thrust cap torqued and thrust is .006"

|

|

Lunati crankshaft is in and spins freely.

|

|

|

Lunati camshaft spec'ed by Lloyd Elliot

|

I drill my own small oil holes in the oil galley plugs to cool the

timing set with oil spray like factory.

|

|

New water pump gear.

|

|

|

ARP cam bolts

|

GMPP extreme timing set.

|

|

Mocking up #1 piston/rod to degree the cam.

|

Bearing clearance .0021" with Clevite HN standard size

bearings.

|

|

Piston is .006" in the hole

|

|

|

Camshaft is 106 deg. ICL exactly as per cam card.

|

Rod shoulder bumped the bottom of the cylinder in this spot.

Took everything apart and ground for clearance and cleaned with soap

and water.

|

|

|

Was meaning to make the rear main bearing a bit tighter so I took

this opportunity to do a mix of standard and .001"

|

|

Top ring at .020"

|

2nd ring at .018"

|

|

Rod bearings at .0020 to .0021"

|

|

|

Rod side clearance .020"

|

Rod bolts at 75 ft-lb for .005" stretch.

|

|

|

The oil pump just barely touched the main stud. I clearanced

the pump just a bit.

|

|

Melling 10552 oil pump.

|

Mr. Gasket .026" head gaskets.

|

|

I measured the chamber volume. I'd say this is give or take

2 cc accurate.

|

Cleaned up the ARP head bolts.

|

|

LE3 heads.

|

|

|

3/8" rocker and rocker studs.

|

|