|

This 92 LT1 already has a good set of TFS heads and mild TFS camshaft

|

Trick Flow rockers

|

|

|

|

|

This is the cleanest head gasket I have seen.

|

|

|

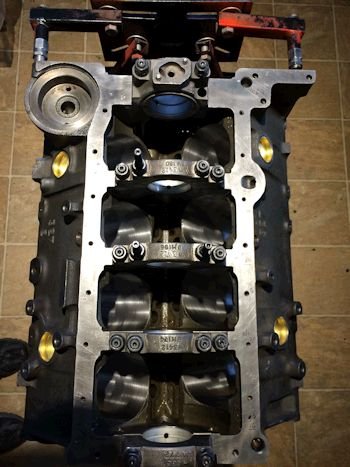

Nice clean engine. The block goes out for

bore/hone/square-deck/main stud align hone.

|

|

|

|

|

|

|

Intake manifold sent to LE for porting. These are photos for my

memory when putting things back together.

|

|

Time to clearance the bottom of the block for stroke.

|

Sharpie marks the spot.

|

|

|

|

|

Callies dragonslayer, 3.75" stroke.

|

Block cleaned and ready for main bearing clearance measurments.

|

|

Another view of the crankshaft.

|

|

|

Mains at 4.4480

|

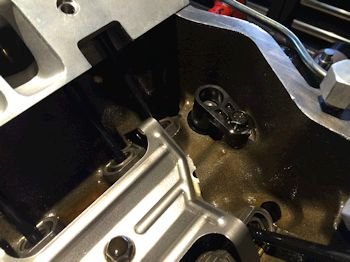

Plug for oil galley. Verified present.

|

|

I had the block align honed for main studs.

|

Clevite P series for stock main caps.

|

|

|

|

|

Crank end play (thrust) @ .005"

|

Rod bearings at 0.0022" with standard size Clevite HN

bearings.

|

|

|

|

|

|

|

|

Top rings at .020"

|

2nd ring at .020"

|

|

|

|

|

Mahle pistons and Callies Compstar rods.

|

All piston/rods installed but not torqued yet.

|

|

Checking piston deck-height. All pistons at .011"

(in-the-hole)

|

A few rods were too close to the block.

|

|

A little more grinding/clearancing.

|

Block is all cleaned and ready for final assembly.

|

|

I saved the installation of cam bearings until now just in case I

had to grind more for rod clearance.

|

Camshaft from Lunati via Lloyd Elliott

|

|

Re-installed the oil galley plug under the rear main cap.

|

Rod bearing clearance at .0020" using standard and .001"

Clevite HN bearings.

|

|

Rod side clearance at .019"

|

Callies Compstar rod bolts torqued to 75ft-lb and .005"

stretch.

|

|

|

Camshaft installation. One snafu was that that cam-pin was

too short to drive an opti-spark. I pulled it and inserted a pin

that was taken from one of my used camshafts.

|

|

Installing the crank sprocket from the Cloyes Extreme timing set.

|

New sprocket for the water pump drive.

|

|

Oil holes for the cooling of the timing set.

|

|

|

Cam pin.

|

Setting up for cam degree check

|

|

Cam card calls for 108 intake centerline and I found it at 107

which is within my goal of being + or - 1 deg.

|

Replacing the oil pump spring with this GMPP 70psi spring.

|

|

|

|

|

Oil pump pickup set.

|

Dip stick tube needs a slight bending to clear the ARP main stud

and nut.

|

|

|

|

|

Mr. Gasket .026" head gasket which will give .037"

piston to head clearance.

|

TFS pushrods, 7.200", 5/16"

|

|

All lifters at 1/2 turn past zero preload.

|

Engine pose before paint.

|

|

|

Now with paint.

|

|

|

|

|

|

|

|

Testing the oil system and lifters.

|

My battery powered drill pushes it to 55psig

|

|

Oil dribbles up into all rockers

|

Oil pump drive installed.

|

|

A view of Elliot Port Works.

|

|

|

|

|

|

Elliott also ported the intake manifold

|

I made the bolt holes in the intake 9/16" wide.

|

|

|

Converted 92 Corvette opti over to vented opti.

|

|

|

Ready for pick up.

|