|

This block was preserved with a thick goop to minimize rust.

|

Headed to the machine shop for clean and inspect.

|

|

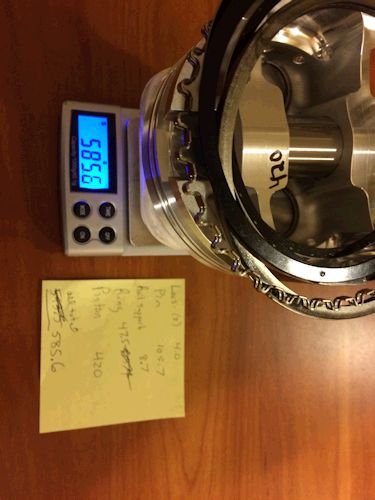

Weights for the balance shop.

|

|

|

Wiseco Pro piston. 1st time I've used this pistons.

Good design underneath.

|

-28cc

|

|

1st ring is .300" down which is nice for tubo-blower motors

|

It's relatively light weight for a blower piston.

|

|

Doing what I can without the crankshaft. The crank is still

at the balance shop.

|

POR 15 black.

|

|

|

Mahle rings file fit at .028" 1st and .026" 2nd.

|

|

|

Block cleaned up and oil galley plug installed.

|

|

Premium cam bearings installed.

|

|

|

LE Camshaft via Lunati

|

|

|

Rod bearing clearance check...

|

Mostly all standard size Clevite H with a few .001" under

mixed in.

|

|

|

|

|

Crankshaft back from the balance shop.

|

|

|

|

Main bearing clearance check. Some mains required the 'x'

size to give more clearance. The target was .0025"

|

|

Final clearance written in sharpee. 0 means standard size

and "x" means one over.

|

Thrust was .006"

|

|

|

Stock timing set provided by customer.

|

|

A look at the 2 bores that have a slight blemish. This is #2

with a bit of rust and so it required the whole motor to go to

4.032"

|

This is #7

|

|

The remainder of the bores look good just like this one.

|

|

|

|

Rods/pistons all installed and rod side clearance is .020"

and Callies Compstar H-beam rod bolts are torqued to 75ft-lb

|

|

Pistons are .008" in the hole

|

Cam degree check at 110 intake centerline and the cam card calls

for 108. (loose chain)

|

|

|

The block deck was not milled because it was nice and square.

|

|

|

|

|

7.150" previously used pushrods work well to get the rocker

tip centered on the valve tip.

|

|

|

The chain is too loose. The chain makes a clunking sound

when you rotating the motor. Now going to install a Cloyes

double roller and convert from 93 opti to the vented opti.

|

Here is a photo of the nearly finished long block. Now

taking a break from the build to deal with the timing set.

|

|

Customer agreed to a vented opti-spark. I made the pin

shorter previously and so now I need to remove it and put in a longer

pin. This pin will not be persuaded. I finally broke it

off and drilled it out.

|

A Cloyes double roller was installed.

|

|

Crank sprocket at +2.....

|

...gives 108 intake centerline exactly as cam card shows.

|

|

Scorpion self aligning rockers.

|

|

|

|

Stock windage tray

|

|

modified and bent to clear the rods.

|

|

|

Stock oil pump.

|

Stock oil pan cleaned up as much as possible.

|

|

I cut and peal back the dipstick hole in the windage tray.

Less metal shaving potential.

|

|

|

Oil pan on. Notice my shop is now in the garage.

|

|

|

|

Valve covers on and dyno manifold on as a dust cover.

|

|

Now we wait for the delivery of the Jeg's

crank damper.

|

I moved the assembly shop into the 2-car garage due to a pending

move.

|

|

Pressure test of the oil system. I used a heavy 15W-40 oil

here so the 60psig is higher than usual.

|

I use an 18v battery powered drill.

|

|

It only took 1 minute for the oil to reach all of the lifters.

|

|

|

Now at the dyno. Morgan International

|

|

|

One delay was that I only had a neutral flywheel for the dyno.

I purchased a stock "external" flywheel and now I can run

any balance combo on the dyno.

|

750 Holley carb

|

|

Hot after the dyno session.

|

Oil and rockers look fine.

|

|

|

|

|

|

|