|

This is the build web page for

ERE383 #6 (Ellwein

Racing Engines LT1-383 #6). It will be built around the free OHIO CRANK that

I gave away as an incentive to purchase this

short block. The rotating assembly will be all forged with

the "Ohio Crank" 4340 crank, Lunati I-beam Pro Mod rods,

Mahle flat-top

pistons and Eagle splayed main caps at 2, 3 & 4 with ARP main

studs.

The block, fully machined and with Eagle splayed main caps with ARP Studs.

The block was align bored very slightly, (see the material removed

from the oil pan rail).

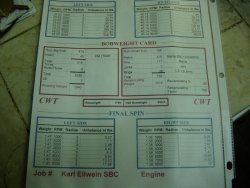

Here is the balance card from McKeown Motorsports

Since this crank is the "lite" version it has less

material in the counterweights. The balance machine wanted

weight added where there exist "no" counterweight.

So Mark McKeown welded material onto the counterweight end as

needed. This was an extra effort that I very much appreciate.

January

14th, 2007

Rod prep. (waiting for paint to dry)

I cleaned all 8 Lunati Pro Mod rods and tested piston pin fit by

"feel".

Now to the long process of measuring rod bearing clearance. I

set the micrometer to 2.1000 and zero out the dial-bore gauge.

Re-check it every now and then because temperature changes and body

heat really screw things up.

Get the bearings installed and torque to .0045"

stretch. See how far off the dial bore gauge is off from zero.

And the results are from .0020 to .0025"

That's what I hope for. The bearings are the big money Speed Pro

Duroshield coated C8-7100CH

Now I'm assembling the rod-piston. Look at that Mahle

piston. It's a work of art.

I used my new pro ring file machine for the 1st time. Normally

this job takes 4 hours, (yes I'm slow). Now it's 1 hour taking

my time.

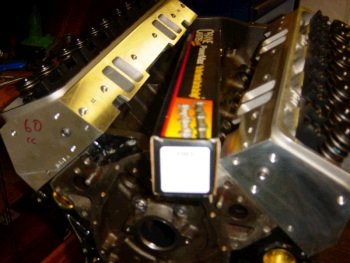

Now for something completely different: This is a new brand of

LT1 cylinder head, the Dart Pro-1 (LT1). The chambers are 60cc

and the intake runners are 180cc. This 383 will be a good test

of their performance potential.

Dart head is cleaned with brake-clean.

Using ARP 12pt head bolts, (big money).

Quick test fit. Looks by eye-ball that I may have to shim the

rocker stands up-higher.

fuzzy photo of new Crane 109831 (GM846) cam.

Cloyes Hex-A-Jjust timing set cam button ground shorter so as not to

interfere with Opti-spark.

Broad photo of the Cloyes Hex-A-Just

M99HVS oil pump and Mr. Gasket oil pump stud.

New stock GM hydraulic lifters.

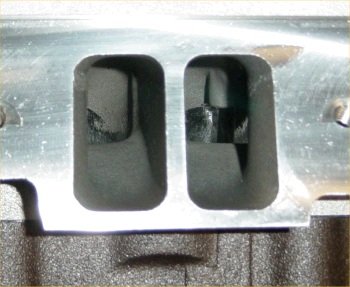

Dart head intake runner close-up.

Red magic marker on valve tips.

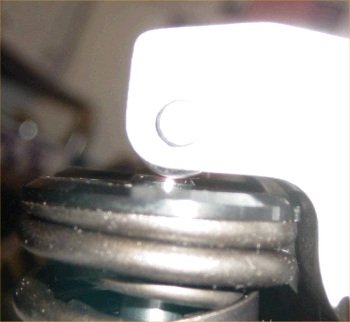

This is the rocker tip to valve tip location with no shims under the

shaft rocker stands.

This is ERE-383 #6 as of 10-21-07

|

Assembly raw detail:

This is the "free" crankshaft, OHIO

CRANK brand, 4340 forged steel 3.75" stroke. It's

part number 43503750LT (lite). The oil holes are beautifully

contoured/chamfered. It has all of the rod journals rifle

drilled.

January 2nd, 2007

The rotating assembly has just returned from the balanced shop and I

set the parts out for a photo shoot.. I'm working with McKeown Motorsports Engineering now and

they performed the expert balance work. They also have been

helping me engineer custom ROSS pistons for a 1200hp 383LT1 project

and they will be assisting in the design of my own custom ROSS

flat-top and D-dish piston for street/strip, nitrous and mild blower

motors.

January 14th 2007

Beginning of short block assembly while waiting for heads/cam:

I have the rotating assembly and fully machined block so now lets

get the block painted with POR-15. This is the base silver

primer.

And now she's POR engine black.

January

21st 2007

Installing the rear cam bearing. These are the nice race

coated Dura-Bond CHP-8T

You can see the cam bearings in this photo

Crank in

And pistons/rods. BAM! A shortblock.

The pistons are 0.010" in the hole. I selected this

0.026" thick Mr. Gasket head gasket.

Right side heads on.

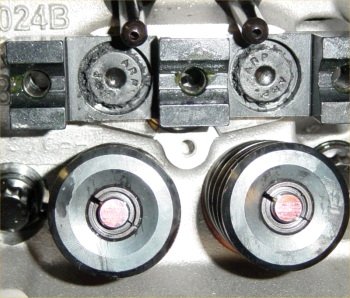

Another item being tested is a set of Probe shaft

rockers. These are the rocker stands.

The Probe rockers look to be very high quality.

Sorry for the fuzzy photo. Is my camera on it's last

leg? I hope not.

Ground-off cam bolts so that Opti-spark fits.

Lucky me. Intake centerline is 107 dead nuts on. This is

the GM 846 cam. The Hex-A-Just was set on straight-up, (no

retard, no advance)

Stock LT1 windage tray is snipped a little bit to clear around the

oil pump body. Many have run their motor without this windage

tray and smoked their bearings only to blame it on a HV oil

pump. Fact is, HV pumps will not pump a sump empty any sooner

than a stock volume oil pumps.

Probe shaft rockers added and adjustable pushrod used to find proper

length. 7.050" is the initial measurement.

Pushrods installed.

The mark is hard to see in the photo but it's right in the

center. With shaft rocker the proper geometry is only

determined by shims or no shims under the rocker stands. The

pushrods have no effect on rocker tip to valve tip location.

The pushrods need to be the proper length to fit in the lash

adjuster nut.

All rockers and pushrods installed and lifter pre-load at 1/2 to 3/4

turn past zero. Pre-lube drill spins at low rpm

(40psig). This also verifies that oil moves up the pushrods

and onto the rockers and springs.

|