|

The crankshaft is an old Callies that has been repaired. The

thrust is weld repaired and the mains are .010" under.

|

The rod journals are standard though.

|

|

Compstar H-beam rods and King HPN rod bearings.

|

Crank rod and main journals verified.

|

|

|

|

|

Washing crankshaft

|

Have I mentioned that I love my parts washer?

|

|

Rods clean....

|

Crankshaft clean...

|

|

Crankshaft rod journals at 2.0990"

|

Main journals at 2.4380" (.010" under)

|

|

|

With King rod bearings CR807HPN all rods are at .0026 to

.0027"

|

|

Filing rings for .020"/.020"

gap

|

|

|

|

|

|

Pistons and rods fresh from the parts cleaner...

|

...waiting for piston ring installation.

|

|

|

|

|

|

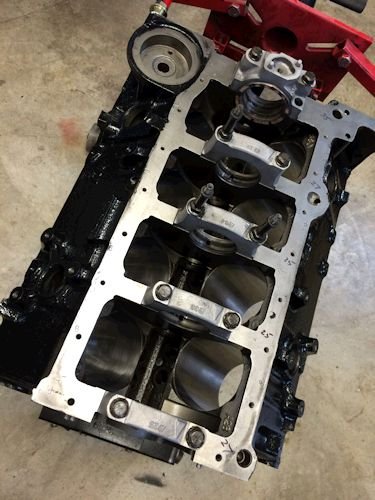

Ten under Clevite bearings installed.

.0027/.0025/.0025/.0027/.0035"

|

|

|

Thrust at .007"

|

|

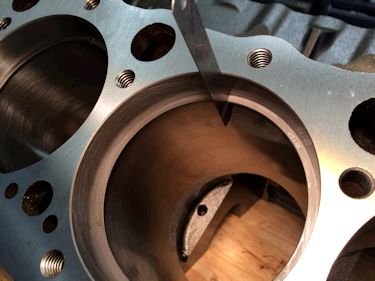

#1 piston/rod installed. Piston is .012" in the hole.

|

Marking the block for rod clearance.

Now the block will be disassembled, clearanced, cleaned and

reassembled.

|

|

The block has been clearanced and cleaned.

|

|

|

|

To the left is a photo of the oil gallery ball-plug. Above

is the notch for the rod bolt clearance.

|

|

|

|

|

|

I made sure the rods cleared the block prior to installing the cam

bearings. I like to leave the cam bearings for last just in case

I have to do more grinding on the block.

|

|

Compstar rod bolts at 75 ft-lb and the feeler gauge is a

.020" (indicating rod side clearance)

|

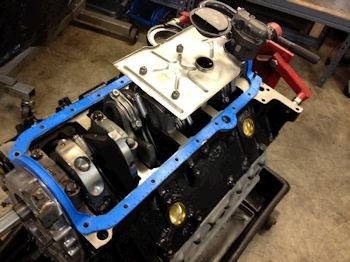

Short block complete.

|

|

Ai Camshaft #234242108

|

|

|

This photo shows the front oil galleries which are threaded for

screw in plugs.

|

The lifter plugs have an oil weep hole.

|

|

|

|

|

One last look before the heads go on.

|

|

|

These are used Ai 200cc heads. Brinkley Auto Machine cleaned

them up and checked the valve springs.

|

Crower lifters and cleaned up "used" lifter dog-bones.

|

|

|

Rockers still to be

determined.

To-do list:

Cloyes timing set.

Oil pump, timing cover, oil pan.

|

|

We have the timing set. The Cloyes comes with a replacement

gear for the water pump drive.

|

Now to show off my new degree wheel. It's huge.

|

|

And accurate. Here the cam intake centerline was found to be

at 104 deg. Just as stated on the Ai Cam Card.

|

|

|

Refurbished, (cleaned up), timing set.

|

|

|

Rocker tip witness marks with 7.200" pushrods.

|

Manley pushrods and Comp Ultra-Pro Rockers.

|

|

|

Melling 10552 oil pump and windage tray installed.

|

|

Bolt-on oil pump pickup.

|

The windage tray is made to clear the longer stroke by simply

bending the tray 'up'.

|

|

I pry the tray up like this. The tray is soft.

|

Getting ready for the oil pan. 1st thing to do is make sure

the rods clear the pan via a test fit and next is to center the rear

main seal housing. I use a couple of feeler gauges to center

it...(no photo).

|

|

|

Pan on and spot painted with POR15 engine black.

|