|

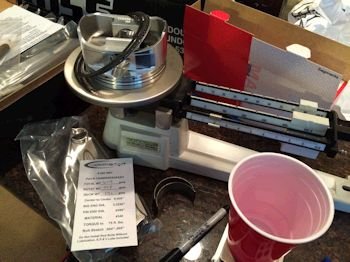

Starting the build process with gathering parts and measuring for

the crankshaft balance bob-weight.

|

I use the small digital scale under the plastic cup because it's

quick and amazingly accurate. I verify it's accuracy using my

lab quality 3-beam scale.

|

|

Custom Ross piston which I had sent a Mahle piston to Ross for an

example. I wanted the ring pack to be like the Mahle but with a

thicker crown so that I cold D-dish the piston if needed for more

chamber volume.

|

The piston compression height is 1.135 as opposed to 1.125"

in the traditional 383 piston. That allows Ross to give a bit

more crown thickness and I have my blocks decked to 9.010" anyway

so the piston will be closer to zero deck. I'm probably going to make

a 383 for my personal car and use this piston and run nitrous.

|

|

|

Piston 432g, pin 119.6,

pin locks 4.5, rings 36, bearings 44, rod 171/448, oil 6

Bobweight = 1753g.

|

|

Now a look at the block and caps. This block was obtained

locally out of a 1995 Camaro. I had it bored/honed/decked and

fitted with Eagle splayed main caps and ARP studs.

|

|

|

I measured bore size using a BHJ 4.030" bore gauge as

reference and it looks like the bores are .001" small.

|

I stuck a piston in the bore and measured with a feeler gauge and

I get .003" clearance. The spec is .004" and so that

verifies that the bore is .001" undersized (it's 4.029).

Back to the machine shop it goes.

|

|

Continuing forward: Here is the Eagle crankshaft.

|

Piston to rod assembly and other measurements.

|

|

Pistons have left and right valve reliefs.

|

2 spirolocks per side for a total of 4.

|

|

|

(Pay no attention to the 25 written on the rod). Standard sized

Clevite CB-663-HN gives .0026 to .0027"

I'm shooting for .0020 to .0022" and so after this photo I

installed a .001" under 1/2 shell in the lower cap and that gave

.0021"

|

|

|

|

|

|

Thanks to Bill Koustenis at Advanced

Automotive Machine in Waldorf Maryland....He honed the block with a

torque-plate and now it's at 4.031 which gives proper piston to

cylinder wall clearance. I measured and now have .005" P -

W. After getting the block back from Bill I clearanced for

stroke at the bottom of the cylinders then washed and oiled it.

These photos show the beginning of the time consuming painting

process. I use a strong, thick product from POR15.

|

|

|

Ring filing and gap measuring. 1st ring gapped at 020"

and 2nd ring at .024". The bore is 4.031 and my ring

checking fixture is 4.030. This is a good chance to see the

difference that .001" bore size makes for ring gap. I get

.017" in the fixture and .020" in the bore for the top ring

and .020" in the fixture and .024" in the bore for the 2nd

ring. These are Mahle 1.5mm/1.5mm/3.0mm rings.

|

|

|

Cam bearing installation.

|

|

Comp cams via Lloyd Elliott.

|

Ooops. Comp sent it with the short dowel.

|

|

Moving onward. Here is my verification that I plugged the

rear main oil galley.

|

Main bearing clearance check. King HP main bearings mix of

standard/-.001/+.001(X).

|

|

|

|

|

|

And we have the Eagle forged

crankshaft installed and with a thrust of .007".

|

|

Oil galleries threaded but the stock plugs go in with oil cooling

holes for the timing set.

|

Mahle ring set on the Ross piston.

|

|

#1 piston in and it's at zero deck height. Even though the

block is decked to 9.010". That is because the pistons were

ordered with 1.135" compression height.

|

|

|

|

Rod bearings all from .021 to .023" clearance.

|

|

|

|

|

Rod bolts torqued to 75ft-lb and .004-.005" stretch.

|

|

|

Short cam pin finally removed. Long one on the left.

|

Cam marking for our records.

|

|

LE Heads from Trick Flow

|

This customer supplied stock timing set has low run-time.

|

|

Degree check comes out to 110 deg. intake centerline. Cam

card says 112 is the spec, (cam is 2 deg retarded due to timing chain

slack).

|

Since the timing set is not adjustable I tried a new timing

chain...still slack and still at 110 ICL. I'll say that that is

close and it will be as good as it gets. I removed the new stock

chain and then re-installed the used chain to keep it a matched set.

|

|

|

Crower lifters soaking in oil. Manley pushrods 7.2"

hopefully will be the proper length.

|

|

|

3/8" studs rockers installed and the 7.2" pushrod.

Looks good. I set the hydraulic preload at 3/4 turn past zero.

|

|

|

|

|

|

Melling 10552 oil pump, high pressure, standard volume.

|

|

|

Pickup bolted on with thread locking compound.

|

|

|

Oil pan from a take-off core. Cleaned and painted with

POR15. Now to let it dry overnight. I'll be back in the

morning to test oil pressure and check for leaks.

|

|

Better late than never: I forgot to insert photos of the

heads. These are Trick Flow GenX Street/Strip GM LT1, 195cc

intake volume, 62cc chamber.

|

|

|

FelPro 1074 head gasket at .039".

|

ARP head bolts at 70ft-lb

|

|

Stock hub needs a key-way and so here is my technique. I use

a dremmel.

|

|

|

Time to check oil flow and pressure and gross leakage.

The drill presses it up to 60psig with 30W flush oil, (used in 2 or 3

engines prior to waste).

|

|

|

|

Now to install the very clean and good looking intake

manifold. I'll seal up all crankcase and intake holes as much as

possible and blow air into the motor to look, listen and feel for

gasket leaks.

|

|

|

Using my valve covers temporarily.

|

|

No air leaks except for at the valve covers.

|

|

|

|

Wrapping her up along with a courtesy set of spark plugs.

|

|

|

New Combo Below. The Ross pistons were too loud due to the short

skirt and 2618 alloy.

|

|

Here is the new rod piston and ring D.S.S. Racing pistons, SCAT forged I-beam 6" rods.

|

This is a D.S.S Racing SX series piston. I saw them at a PRI show and

was fascinated. Good quality. 4032 alloy for a more

streetable motor.

SX

Pistons Link

|

|

The piston ring package is 1.5mm, 1.5mm and 4.0mm oil ring.

I like the thicker and higher tension 4mm oil ring.

|

New bobweight = 1719.4g

|

|

Here is the replacement block fresh from Golen via R+L Carriers

truck freight.

|

And after cleaning with soap/water/oil. Notice the 4-bolt

caps and ARP main studs.

|

|

|

I am checking the bores to see if they are close to 4.0300"

which is referenced from my bore gauge standard in the next photo.

|

|

This is my big $$ bore gauge standard for 4.0300"

|

There are Total seal non-file fit rings and the top ring comes in

at .018" which is a good gap for street strip all natural.

Notice the chamfer at the gap near the cylinder wall. That is on

all the top rings. Very unusual. But Total seal knows what

they are doing.

|

|

The 2nd ring needed to be gapped by me to open it up to .018"

and it did not come with a chamfer. It is very square as are

most ring sets. The top ring must be designed to let some gas

through to the 2nd ring where it then will not pass to the crank case.

|

All rings at .018" gap.

|

|

#5 cylinder bore is blemished. The rings catch on this

pit. Cannot use the block without going to a .040" over

bore.

|

Time to go clean up another block to use in place of this one.

|

|

....A couple of months later....I sourced a block locally:

Sent to the main cap shop for installation of Milodon main caps and

then bore/hone/deck.

|

These are the Milodon caps.

|

|

Since this is a local block I have to do the block prep and

clearance work by hand. After that comes the rotating assembly

test-fit. So far so good. Lots of clearance for the rods

outboard.

|

For this type of rod I also need to clearance at the cam side of

the cylinder bore. Maybe you can see where it is ground down in

this photo near the cam-tunnel.

|

|

Piston is in the hole .007"

|

1,2,3,4 installed and all good so far.

|

|

All 8 piston/rod assemblies installed. #7 rod is too close

for comfort. Not a problem. I expected to have to do

additional grinding thus the mock-up. That is why I did not

install the cam bearings...in case of additional grinding.

|

|

|

To the right you may be able to see the rod shoulder is almost

touching the block at the yellow marked spot.

|

|

|

After grinding on the block slightly to give more clearance for #7

conn-rod the block was cleaned with my Saftety-Kleen parts

washer. Now I can install the camshaft bearings.

|

Here is a view of the front oil galleys where I threaded them for

pipe plugs. Recently I found a source for plugs with oil pin

holes and that is what I'm using in the lifter galleys. The

center camshaft oil galley takes a non-vented plug. Here is a

photo of the center oil galley that show that you cannot insert the

plug too far as to block the oil passage.

|

|

All plugs installed.

|

Rear main cap oil galley plug. This plug divides the oil

passage from and to the oil filter. Forget this plug and you end

up bypassing the oil filter and thus you'll have dirty oil, (but

higher oil pressure).

|

|

Here is a view of the rear main cap oil passage and where I

enlarge it with my Dremmell tool to align with aftermarket bearings.

|

Main bearing clearance: King premium bearings, Milodon main

caps.

|

|

So far the clearance is a little tight with standard size

bearings. The main cap shop set things too close to

"stock".

|

A full set of "x" (.001" oversize) bearings will

put us right in the .0025" area, (bearings are on order).

|

|

Re-stock of X bearings have arrived. I needed 3 more of them

to install in 1,2,3 mains.

|

Also have the rear #5 cap with one x and one standard bearing

shell for a 0.0032" clearance.

|

|

|

SCAT crankshaft thrust clearance checked at .003" by feeler.

|

|

Thrust is .004"

|

Here is a good look at the cylinder bottom and piston clearance to

the crank counterweight.

|

|

Rod bolts to be stretched to .005"

|

|

|

.020" rod side clearance.

|

|

|

|

New GM rear main seal housing.

|

|

The short block was sprayed with machine preserving oil so as not

to rust if setting in a damp warehouse.

|

R + L Carriers.

|