|

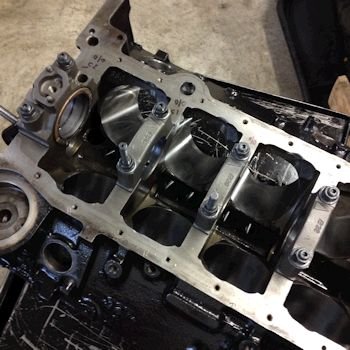

Photo to the

left: After my blocks are returned from the local machine

shop I will bolt on a torque plate and check the bores for

roundness and taper and then check for piston to bore

clearance. The bore gauge here is set to my 4.030"

standard and it's dead-on.

Photo above: I still have to clearance the bottom of the

block for the rods. I did a 1st draft so to speak and now I

can concentrate on where the rods actually hit. The Eagle

rod requires some clearance at the oil pan rail. (Callies

rods do not). |

The photo shows the area near the cam tunnel that required

clearancing. H-beam rods with the flat big-end sides do not

require a lot of clearance here but the I-beam rods with the

shoulder bump require it. |

I did a second round of grinding and still have to touch up at a

few spots. Most of the bores were good. |

I took a break from grinding to get some painting completed.

Here is the POR15 at the front of the motor. |

The front oil galleries are threaded for 1/4"

NTP. The lifter valley plugs will be vented for oil spray to

the timing set. That is a big block Chevy part and easy to

integrate into the SBC LT1. |

|

Rather than finish the block clearance work (it's 30*F

outside) I'll work inside at 65*F and assemble rods/pistons.

|

First laying things out and checking which rod bolt is

installed for torque/stretch spec. |

Also I check the pin fit. It the pin slides out of the

rod with only gravity assist then it's good. |

|

This is an Eagle 4340 steel crankshaft. It's balanced to

1803g for the Eagle H-beam rods/King bearings/Mahle pistons. |

Rod journal is 2.0990" and mains are 2.4491" |

|

Rod bolts @ 63ft-lb

(.006") stretch. This gives 0.0025" clearance with

the premium King CR 807XPN rod bearings. |

|

After completing the additional clearance/grinding I washed

the block thoroughly with a mix of hot water and simple purple

then dried and oiled it.

|

This is a photo showing the ultra premium main bearings by

King. The MB 557XP (tri-coating). |

Here the mains are on the tight side of the spec. This

will be good for sending more oil pressure up to the rod

bearings. It's a tad tight for all out race motors or forced

induction but good for street performance motors. |

Mains are at .0015" #1, 2, 3, 4 and .0025" for the

#5 |

|

The

The crank end play is .006" |

Installing camshaft bearings. Durabond premium. |

I pulled the rear main cap off because I realized I did not

install the oil galley plug. Better late than never.

Re-measured the crank end play and verified at .006". |

Lloyd Elliott camshaft. .580/.593" lift and

223/231/112 duration at .050"/lobe separation. |

|

Just now noticed that Comp put the wrong cam pin in.

This is the standard SBC stubby. |

Photo verification of oil galley plugs. |

Nice timing set. This is the Cloyes extreme. |

Thankfully I have a premium pin pulling tool. Had to get

this due to Comp Cams short pins. (I'd say every 5th

camshaft will have the short pin). |

|

Short pin shown on the left. New stock long pin

installed and looking good. |

Camshaft degree check. Here I'm dialing in TDC. |

Now looking for Intake Centerline. |

I measured 108.5 ICL on the 1st try and 107.0 ICL on the 2nd

try. I'll call it 108. That is exactly as stated on

the cam card. |

|

|

File fitting of the Mahle 1mm ring pack. I went with a

gap that is between the perfromance street gap setting and the

circle track/drag racing (Naturally Aspirated) gap setting.

.020" 1st ring and .020" second ring. I use my

bore gauge for the quick check with the feeler and then I verify

that with the ring in the actual engine bore. |

|

All pistons are .012" in the hole. I try to

minimize the block decking so that the intake manifold fits

better. In other words...I usually do not "zero"

deck a block. |

0.022" rod side clearance. |

Rod bolts clear the block. |

Here is the left front of the block where the Mr. Gasket and

the Cometic head gaskets do not allow for oil drain back. I

clearance in this area as a matter of routine. |

Mr. Gasket head gasket. (.026"). |

LE Heads |

|

LE2 head on and head bolts torqued to 70ft-lb |

|

A few valve train components. Note the adjustable guide

plates. That will allow for exact rocker tip alignment over

the valve tip. |

One head had the thread inserts installed too shallow.

The bottom tang interfered with the rocker stud. I ended up

threading them down a few turns and also knocking off the tang if

it poked into the intake runner. |

See here: Thread insert tang might one day break off and

fall into the cylinder. |

Here is a photo after breaking off the tang. |

Rockers on and guide plates adjusted. |

|

Reluctor on for proper damper spacing. Gasket gooped with

Right Stuff RTV.

|

Please excuse many of the out of focus photos. This is

an old iPhone 4S taking the photos. My newer phone is

broken. |

Lots of bending "up" of the windage tray. The

Eagle rods have rod bolts that protrude more than most brands.

|

|

From this photo you cannot really see the windage tray clearance

hump. I use the stock windage try for all engines. I

don't trust the built in trays of oil pans. Here we are using

a stock pan and so this tray is a must.

|

Rockers all adjusted (1/2 turn past zero lash). |

A photo for the records to show the head numbers.

|

Rear main seal housing being centered prior to full torque of

the bolts. It's .004" feeler space at each of the 3

locator tabs. |

|

Oil pan test fit. #7 rod bolts hit at this spot. I

dimpled it with a hammer. Also dimpled the front bottom of

the pan for #1 & #2 rods...(not shown). |

POR-15 pain applied to the pan.

|

MSD cap and rotor installed. The old core opti was very

dirty. I decided not to pre-wash the core opti in case fluid

made it's way inside and messed up the optics. I just hand

wiped the core parts after assembly. |

|

OK now I have a

slight snag. The ATI hub is binding during press-in. I

stopped for today and will be back at it tomorrow. |

Turns out that I needed to hone the ID of the hub. It was way

too tight as an interference fit. You can see the remnant of

the line where it was being gouged by the crank nose.

|

The hub pressed on nicely. The crankshaft bolt you see is

the ARP 1-1/16" 12 point. You'll never slip your wrench

off of this crank bolt. You might be frustrated one day when

you find out you don't have a 1-1/16" 12pt socket and have to

go to the parts store or Lowe's to buy one. |

ATI hub for B-body. It is quite long. Easier to install

the opti though. An F-body hub is so short that it may be

difficult or impossible to install an opti with the hub on.

|

One thing I know about the MSD cap and rotor kit is the 4th

fastener (good idea) will bump into the timing cover and not allow

a complete seating of the opti. I simply grind down on the

back of the fastener here you might see it in the fuzzy photo. |

Opti on without binding.

|

Oil system test. Satisfactory at 58psig and oil dribbles at

the pushrod-rocker. |

Don't forget the oil pump drive gear...(it goes before the intake

manifold HA!). Here I simply swap gears onto the old core.

|

That's it for

today. Engine goes to the dyno in a few days. Stay

tuned. |

Here are the dyno only parts and the process to get the engine

ready for the engine dyno. Right now I use a carburetor so the

GMPP manifold is installed. In the near future I plan to use

an EFI system and the customer's manifold.

|

GMPP LT1 Carb manifold. |

Now a jury-rigged timing pointer is installed and TDC verified

via piston stop method.

|

An MSD distributor is installed at about 37 deg BTDC. |

Customer valve covers cleaned up and installed.

|

My CIA headers installed. The carburetor is at the dyno

shop. I use an electric water pump for the dyno

session. Stay tuned for the results. |

Here we are at Morgan Racing Engines with Jim Morgan. It's

about 15*F outside and 40*F in the dyno room.

|

The dyno cell draws air from the adjacent large shop, (to give

cooler air when it's hot out). But now it's good to be

getting somewhat warmer air. |

|

|

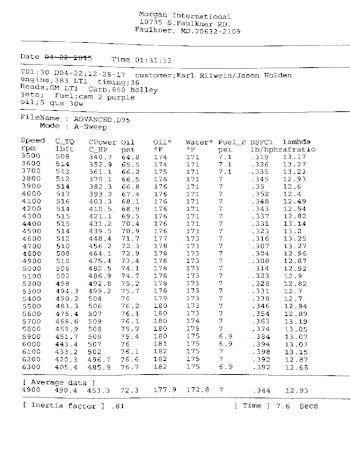

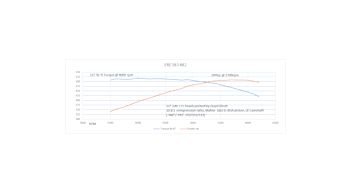

509 hp @ 5700 rpm and 517 lb-ft @ 4000 rpm. Check the

chart. The cold air made it a tick on the lean side but that

usually makes for good power. ;)

|

|

|

Now the engine is undressed from the dyno parts and along with

that it receives a minor visual inspection. Intake valley

looks good. Rockers look great. |

|

I collect the oil in a clean tray and let it sit for a while

to look for metal or water. This dyno oil looks great! |

Installed some of the owner supplied parts such as a TFS

throttle body and TFS 30lb-hr injectors and AC-Delco water pump with

160 T-Stat.

|

Taylor wires. Nice fit. |

|

|

|

I have the motor

bolted down to a pallet but still need to get a sturdy box to cap

the engine and then wrap it up and ship her down the road to

California, USA. |

|

Ready for shipment. |