OK! It is about time I got started with ERE-383

#96. This is the "budget" main cap version which is

hardly budget. The main caps are pretty good. They are

4-bolt but not billet steel. ARP main studs are used which

helps beef things up. Here is the block and I'm beginning to

get it ready for paint. I put on sacrificial rear main seal

and timing cover and oil pan to help me mask off areas. I wipe

it down with acetone (or brake clean). The paint is the

Eastwood 2 part "2K" high temp ceramic.

|

Here is the drivers side front of block where some head gaskets

block and restrict the oil drain-back. I always clearance in this

area no matter what head gasket is used.

|

|

Painting finished. Next on the agenda is rotating assembly

mock-up to check for clearance.

|

|

Ok, moving forward. It is time for engine #96. Today

I'm going to tap the front oil galleys for threaded plugs and

clearance the bottom of the bores for rod clearance at the

cam-tunnel side. Then clean the block, assemble

crank/rods/pistons to make sure all clears. Possibly I'll need

to do further clearancing. Cam bearings will be installed

after I know that there will be no more need to grind on the block.

|

Here is the block after I clearanced at the cam tunnel area for

rod stroke. Notice it is no longer painted. The pressure

washer was taking off the paint. I must have prepared the

block poorly for accepting paint. Better that happens to me

than the customer. I'll do a better job with the next paint

job.

|

See the areas that are typically clearanced for rod stroke. It

is the bottom of the cylinders inboard and outboard. You won't truly

know that the clearance is enough until you mock up the rotating

assembly. That is today's goal.

|

Here is the 4340 forged steel Eagle crankshaft, (Neutral

balanced) at 1759g by Eagle.

|

I might as well measure rod and main clearance while I mock up

the rotating assembly. Rods are all at 2.0992"

|

Photo for proof that I installed the oil galley ball.

|

I put the crank in with just #1 and #5 caps and while I'm at it

I checked #5 thrust bearing with feeler and by dial bore.

.005" by feeler on each side and .007" end play by dial

gauge.

|

|

Assembly of #1 piston and rod and King CR807XPN bearings.

(Standard Size). All rods are from .023 to .027"

clearance.

|

|

The 1st rod mock up, (#1), is good. The rest were ok but a

few were too close for my comfort. I have the areas marked for

grinding, (tomorrow).

|

I run into trouble with Eagle rods almost every time. The

outside edge of the pin bushing is too tight but only the outside

edge. All the rods seems to have a lip that needs to be buffed

to allow the pin to pass and fit nicely in the bushing.

|

I do this by hand.

|

See that just the outer edge of the bushing is buffed. Now

the piston wrist pins fits perfectly (on all 8 rods).

|

|

All mocked up. Now to removed the pistons/rods and crank.

|

Before I re-grind and re-paint I'll check all main cap bearing

clearance. King MB557XP bearings.

|

From .022" at #1 main all the way to .035" at #5 main.

|

|

Here are the sharpee marks where I need to grind some

more. I'll do that tomorrow and also paint.

|

|

Ring filing. Going with .020" 1st ring and .020"

second ring for hot street power and occasional strip.

|

Here is my trusty ring filing set up.

|

|

|

Cam bearings going in. Allen key-wrench to verify oil hole

alignment.

|

|

|

Camshaft installed (and used but good water pump drive and new

Cloyes gear). The camshaft is Lloyd Elliott from Lunati.

A streetable 231/239/112 duration @0.050" and .571/.587"

lift with 1.6 rockers.

|

|

Thrust is .006 after torquing down the rear cap.

|

|

Pistons ready for the rings.

|

|

One problem piston. Look closely at the 2nd ring land and

see a deformity. Could I have mishandled it and dented

it? Possible but I don't see any scratches or "dent"

witness marks. 1st time I've seen any blemish from

Mahle. Anyway...that's the breaks. I will be getting a

replacement on order Monday.

|

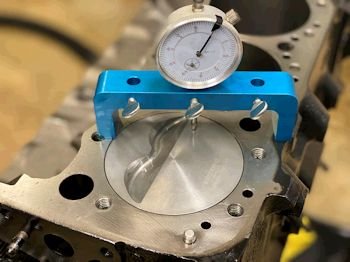

In the interim while I wait for the 1 piston I can check deck

height. I measure in the center and on both fore and aft of

the piston and take the average. The piston rocks in the

bore. .010" aft and .014" forward. (we'll go with

.012"). That makes static compression ratio 11.05:1 with

FelPro 1074 head gasket. (if the heads are 62cc). I'll measure

the head chamber soon.

|

OK, the new piston arrived and it is installed, (no

photo). Here is the beginning of camshaft degree

verification. Intake centerline measured at 108.5* and the cam

card spec is 108. This is an LE camshaft with

.571"/.587" lift and 231/239 duration @ .050" and

112* lobe separation.

|

|

Then I went to the rest of the pistons to verify how far the

pistons were in the hole. They are all in the hole 0.012"

(give or take .001").

|

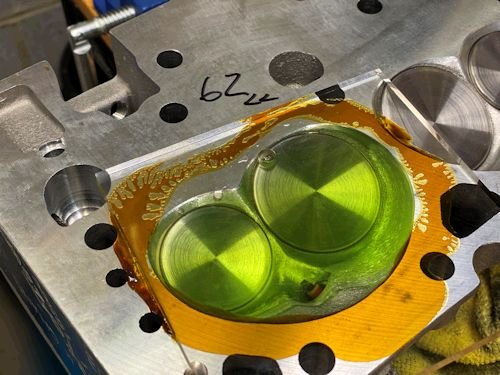

Now I measure one chamber to get the combustion chamber

volume. I measured 62cc. That puts static compression

ratio at 11.05 with the FelPro 1074 head gasket and -5cc piston and

-.012" piston-in-the-hole.

|

|

|

|

ARP head bolts with stainless outer bolts.

|

torqued to 70ft-lb

|

|

Oil pump and windage tray installation. The oil pump is

the Melling 10554ST which is the premium shark tooth. Standard

volume.

|

Canton oil pump pickup.

|

|

Oops. Now I notice that the oil pan is 8" deep.

This pickup I have is for a stock pan at 7". Always

measure. I'll have an 8" pickup in a few days.

|

|

|

For now I put the oil pan on as a dust cover. Check back

in a few days when I have the 8" oil pump pickup. The

engine is almost finished.

|

Timing cover on. Now installing the seals. This is

my water pump seal installation tool. Tapered nose to allow

the seal to slide on...

|

...then hammer it home with a socket.

|

|

Used (core) lifter hardware. Cleaned up and ready for

installation.

|

The lifters are my favorite stock style replacement. These

are Crower 66330-16

|

The oil pump drive gear gets a new ACDelco gear.

|

Installed the oil pump drive gear just temporary. I want

to make sure all is good. Later it will be removed in order to

spin the oil pump with a drill.

|

Now testing for pushrod length with my Lunati pushrod length

gauge. It comes out to 7.180" and then add the lifter

preload of 1/2 turn (.025") and you get dang near 7.200"

pushrod. Remembering that the 7/16" stud is 20 threads

per inch and lifter preload should between .020" and

.060". Just know that 1 full turn on this 7/16"

rocker stud is .050" of travel and so you can do 1/2 to 1 full

turn of lifter pre-load.

|

The Lunati lifters sit pretty good on the valve tips. The

guide plates were installed by Lloyd Elliott and he did a good job.

These are Lunati 15315-16

|

A quick test of the rocker tip to valve tip shows A-OK.

|

|

|

Cleaning up parts. I take the tin pan off the bottom of the

manifold just in case there is debris or sludge in here. It

was not all too bad but this photo is taken after a round of

cleaning.

|

Cleaned up a core rear main seal housing.

|

The intake is on temporarily to act as a dust cover. Also the

fit can be looked at to see if the bolt holes line up and the

china-wall and head mating angle. All is good with this

manifold.

|

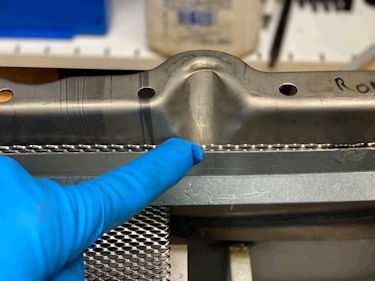

.003" (and sometimes a .004") feeler gauge at the

alignment nubs while tightening the bolts.

|

This is a close up of one of three nubs. That is a .004"

gap. All 3 nubs have a .004" gap. That ensure the

housing is center and the seal won't leak.

|

Speaking of seals this is new to me, (customer provided). The

National Oil Seals brand. It seems to be pretty good quality.

|

And this is a photo of the camshaft plug and rear oil galley plugs.

|

New oil pump pickup is here. This is for an 8" pan

and also "drag-racing" style which keeps the pickup

further back. This was needed due to the oil pan having a trap

door baffle in the spot that a stock pickup would want to be.

|

I made this special little stubby nub of a torx bit in order to

fit under the pickup and to be able to tighten down the oil pump

fastener.

|

Hard to see here but the pan is 8.0" deep and the pickup

goes to 7.50" depth. That gives 1/2"

clearance. A bit larger than usual but not out-of-spec.

|

I hope this screen does not interfere with the dip stick

tube. We will soon find out.

|

Wow! What I thought was an oil pan gasket turned out to be

a box of multiple gaskets. The box was previously opened and

the gaskets looked to be touched by grimy hands but they are still

good after cleaning.

|

Dip stick tube fits well and does not hit that oil pan screen

|

|

One last look at the bottom end. I put RTV on the gasket

at the corners just in case the pan does not fit exactly

perfect. It's an unknown pan to me. Although stock style

pan, (like this one), fit best and seldom need RTV to seal up...I

went conservative here and used RTV. If possible it is nice to

not use RTV in order to be able to remove the pan in the future.

|

Putting on an MSD cap and rotor. First I made sure to

clean the base and then blow it dry.

|

Also always reuse the stock rotor screws and put loctite on the

threads.

|

Later today I'm going to paint the intake manifold.

|

|

|

|

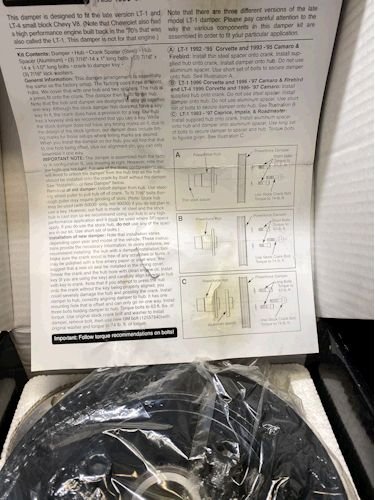

I took a photo of the Professional Products damper #80030

because I really like how you can cover all the LT1 engines with one

part number. They have all fitment covered, from Fbody to

Bbody to Ybody, (but not LT4) It is a reasonably priced unit

for pretty good quality.

|

This is DE1653-RED from Dupi-Color (Engine paint).

|

I wish it were more Red and less Orange.

|

Looks pretty good I think. But if it could be a red as the

MSD Opti that would be AWESOME.

|

|