|

Tearing apart the engine core. I have numerous hub pulling

tools.

|

This is the view after removing the windage tray and oil pump.

|

|

#6 rod bearing is spun. The rest are mostly ok.

|

It is a nice day today and so I have the garage door

open. Good light for photos.

|

|

Main caps off.

|

Crank shows #6 rod and #4 main spun.

|

|

In the mean time...the oil cooler/oil filter adapter is cracked in

half.

|

Maybe this caused coolant to seep into the oil and contaminate it,

which caused the rods/mains to spin.

|

|

Look at the cam bearings. They are all in brand new condition.

|

Cam bearing is absolutely perfect conditon.

|

|

The front cam bearing is pristine.

|

Notice the black heat damage at #4 main.

|

|

Here is a close up. This is from the spun main bearing.

The heat blackens the journal and makes it brittle. I will

have the machine shop check for cracks.

|

It is possible that this is brittle and cracked but chances are it

is ok. I have a 350 LT1 that has 2 blackened mains and it is

still running strong after 10 years.

|

|

The block is ready for the machine shop.

|

The mains will be align honed using ARP and Milodon studs.

|

|

Balance notes: Data for the balance shop.

|

Howard's billet rods, (6.0")

|

|

Rod is simply checked to see if it is in fact 671g total like the

rod build card says.

|

It is 470g big end and 201g small end via the card and 671g total

verified. by scale.

|

|

Neat packaging of the billet rods.

|

Love the shipping box for the rods.

|

|

For the piston/rings etc I weigh all

separate and then all as a set. Piston 413g, Rings 35g, locs

2g, Pin 116.5g (and weighed as a unit = 566.6g)

|

The block came back from the machine shop blessed off and in good

shape. So now I mock up the rotating assembly and mark the

block for clearance grinding.

|

|

Mahle piston and billet rod.

|

Another photo of the billet rods.

|

|

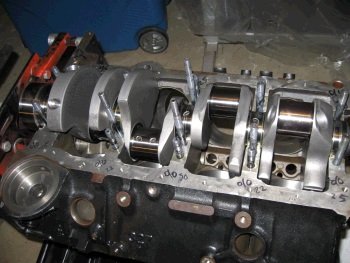

Crank in place. This counterweight is wide and I need to give

extra clearance at this spot.

|

|

|

|

Rod/piston in and the block is marked at each location for grinding.

|

|

Block is now clearanced and cleaned. Time to move

forward. Camshaft in.

|

Swain coated main and rod bearings.

|

|

Howard's forged crankshaft.

|

bearing/assembly lube.

|

|

Caps on and torqued. Thrust is .007"

|

Piston/rod assembly.

|

|

Nice view of the billet Howard's rod and Mahle piston.

|

Ready for piston rings.

|

|

Ring file-fitting. Top at .022" and 2nd at .024"

|

Rod bearing clearance .0022"

|

|

|

Degree of cam. It should be 106 ICL

|

|

Nice view of the Rollmaster timing set from Scoggin-Dickey

|

Cam timing at 106 ICL (with the crank sprocket at -2)

|

|

Installing the pistons.

|

A photo of the Swain coated rod bearings.

|

|

Stretch rod bolts to .005"

|

Clearanced just enough.

|

|

Bottom.

|

Cleaned up the windage tray and bend the center of it to clear the

rods.

|

|

Oil pump pickup at about 7.5"

|

Block head-deck cleaned and ready for gasket.

|

|

Piston is .010" down in the hole. This is a GM Impala

gasket at .029"

|

Head bolts with stainless outer row.

|

|

|

|

|

|

Ai provided pushrod length checker.

|

|

7.050"

|

Water pump drive hole sealed with Kennedy $.50 piece.

|

|

Oil pan cleaned and blown with air.

|

I'll touch up that oil pan later with POR15

|

|

|

|

|

Oil pressure check...60psig.

|

Prep for intake manifold

|

|

|

Photo of the SFI spec damper.

|

|

New rear main seal installed, a bit more paint added in spots that

were blocked by the engine stand.

|

Pushrods arrived yesterday. Installed today and set a 1/2 turn

past zero lash.

|

|

|

|