|

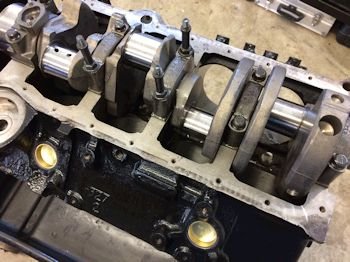

This is a pretty nice engine core. The owner desires it to be

refurbished to just like new using as many stock parts as possible.

|

|

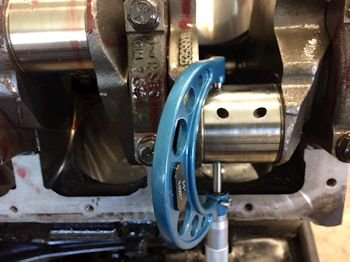

The stock serpentine damper/balancer is banged up a bit.

|

|

|

|

Before removing the intake manifold I cleaned and blew out with air

the debris. That is so that I can identify debris that may be in

the engine and I don't want to mix that up with dirt that I caused to

fall into the motor.

|

The intake valley looks great. No debris. No bearing

dirt. No sign of head gasket leak.

|

Rocker/valve springs look good and the heads look good.

|

|

|

|

|

|

Water in the oil pan but that is not enough to be from a head gasket

leak. That is from condensation. The oil pan is free of

debris.

|

Crank and rods look good.

|

|

|

|

|

|

Pistons and rings are all in good shape but the rod big-ends are

egg-shaped which is pretty normal. The rods will be

reconditioned.

The mains look good.

|

|

|

|

Piston bores look great. A mild hone is all that is needed.

|

The cam bearings are in good shape too.

|

|

|

|

All items are now back in my shop after a nice stay at the machine

shop. Block is painted and cleaned.

To the right is the photo verification that the oil galley plug, (in

this case a steel ball), is installed.

|

|

|

|

Stock crankshaft was polished.

|

|

|

Using Clevite "P" series bearings, (conform well to soft

stock main caps).

|

|

I set clearances on the tight side of the spec. since this is a

stock rebuild and not a high rpm race motor.

|

|

|

|

New cam bearings shown to the LEFT:

Big Block Chevy oil galley plugs with oil holes shown above which take

the place of the stock plugs.

|

|

|

Main bearings set up for long-term-storage via the assembly lube.

|

|

Brand new Cloyes stock LT1 timing set.

|

The Cloyes stock timing set is a bit different than stock in that

the cam gear is billet.

|

Valve train parts cleaned. Lifters soaking in 30 weight oil.

|

Crank rod journal at 2.0991"

|

Rod bearing clearance at 0.0024"

Notice to the right that I use an ARP rod bolt guide tool to install

the piston/rod.

|

|

|

The block was not decked, (just

cleaned). This shows that stock deck height is around

9.025". The piston is in the hole -0.025"

|

|

Rod bearing clearance 0.0020" with King CR807SI

bearings. Standard size.

|

The crankshaft rod journal is 2.0991" (for the records).

|

|

Crankshaft endplay is 0.004" and rod side clearance is 0.012

to 0.016"

|

New Melling M155 oil pump. I need to get the 3/4"

pickup.

|

|

Heads had a mild valve job and deck straightening.

|

They also received new stock valve springs.

|

|

|

Heads on and new stock head bolts torqued to 65ft-lb with thread

sealant on the threads and ARP lube under the bolt-head.

|

|

|

|

|

Lifters-Rockers installed and adjusted to

1 turn past zero pre-load.

The timing cover was cleaned and new

seals were installed, (water pump, opti and crank).

|

|

Here is the new 3/4" oil pump pickup.. I'll explain how

I accomplish the task of pressing it onto the oil pump.

|

Here are the tools. I freeze the pickup and heat the oil

pump after removing the relief spring. I have no idea if heating

the pump with the spring in place will change the tension of the

spring but I remove it anyway. The tool on the vice is designed

to allow me to hammer the pickup into the oil pump.

|

For this M155 oil pump I changed the relief spring to the GM

#3848911 for higher pressure.

|

F.Y.I.: I'm not a fan of

welding the oil pump pickup. The factory does not tack weld

it. The pickup will move if you hit it hard enough but that is a

moot point when the oil pan is installed.

|