This is the view immediately after pulling the intake

manifold. A little bit dirty in the intake runners but

generally very clean considering.. |

Notice how the Chapman ported TFS LT1 heads do not match the LT4

intake manifold gaskets. I'm always running mismatched parts

it seems. |

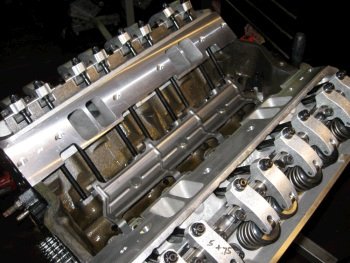

The Jesel rockers are going on the new Dart heads. These TFS

heads are staying with me. |

This is an all business valve train. Thick wide valve

springs, mechanical roller lifters, Jesel shaft rockers.. |

The shaft rockers and pushrods hopefully will fit the motor with

the Dart heads installed. |

Almost ready to pull the heads. |

One head off. |

And the right head off. Pistons are pretty clean. Ring

seal was super just prior to pulling the motor. I'm a big

believer in not re-ringing/re-hoing if there is no reason

to. This short block will be given a good visual inspection

and maybe new bearings but nothing more...oh also a new Ai

camshaft for hydraulic lifters. |

Now to the bottom end. The oil pan off and the bottom looks

nice at first glance. |

No metal parts, no chipped or cracked pistons...all looks good. |

Another view after just pulling the oil pan.. |

Notice the Milodon main caps are using bolts and not studs,

(except at the windage tray location). |

New main bearings installed, (Mahle stock style at #1, Clevite H

at 2, 3, 4 and re-used Federal Mogul stock style at the thrust

because it was in perfect shape) |

Thrust is .008" before torque of rear main cap. |

Thrust is .008" after torque of rear main cap. |

This is #1 piston looks like and all the others are in pretty good

shape after years of service. The rods are all getting super

expensive Federal Mogul "H" style coated bearings,

(because that's all I have on the shelf for a .010"

under size). |

The Dart heads new in box. |

More photos of the Darts. |

One Dart head on the motor just to pose for the photos. |

Un-ported but with lots of potential. The valve springs are Comp

987 |

And another

view. |

The Ohio Crank crankshaft was purchased as a blemish and the blem

was that it has .010" under rod journals, (and standard

mains). It's a very good quality crank otherwise. So

the only 10 under bearings I had were these premium coated Speed

Pro's, (Federal Mogul). These cost about $100 bucks for the

set. Nice. |

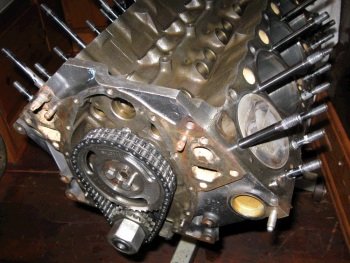

The timing chain is a bit loose but it degreed well, (106 ICL

right on the cam card spec.) |

Piston is .006" in the hole and that means I can use a GM

.029" Impala head gasket.. |

The pistons cleaned up real nice. |

rod bolts torqued to 70ft-lb for .005" stretch. |

Back in 2005 I took a grinder to this rod bolt for extra

clearance. |

Oil pump on. I tightened up the oil pump relief spring by giving

it's set screw 3 full turns clockwise |

A view of the dipstick |

This makes it tricky to read the oil level but just knowing that

it scrapes along the main cap when removing the stick will help

you interpret the oil level on the stick. |

rod bolts "not" hitting the windage ary |

Another view |

Using GM Impala SS head gaskets |

Gasket on. |

Nice box-stock heads |

You might have to shorten your water steam-line banjo fitting to

fit in there. |

That's the hole and you can see water jacket just inside the

hole's opening |

Darts bolted to block:

I'm using the head studs from ERE3 . |

New GMPP hydraulic lifter kit. |

Nice pose. |

Now I hope I have the right size pushrod. |

The rocker tip is set on the valve tip |

Right now I'm using 7.15" pushrods because that's all I

have. They are just a bit too long. |

I stripped the shaft stand bolt hole threads in one of the

cylinder heads probably by using too short of a bolt. (Jesels come

with a short and long version of the shaft stand bolt). Took

the head to the machine shop and had heli-coil inserts installed.

(2 day delay). |

Now the stand is installed after the head repair and I also have

7.050" long pushrods from CV products, (via Ai). The

are very sturdy and stiff pushrods. |

One pair of Jesel rockers are on and the adjuster nut turns 1.5

turns until zero lash and then I turn it another .5 turn, (2.0

turns total from fully backed out). |

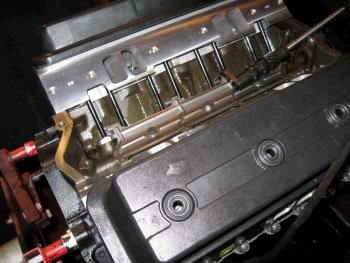

All lifters in, (new GMPP hydraulic lifter kit). All rocker

pairs on and adjusted. |

A final look at the bottom end. |

Oil pan on. Remember this is a "used" motor so the

pan has seen better days cosmetically. |

another view. |

And another view. |

Here is the Impala SS sized hub from ATI. The original ERE#3

had an Fbody hub and that is shorter than the Bbody hub. |

This shows the steel drive shaft that is used with the Titan

gerotor oil pump. |

Again...notice that these valve covers are quite used. There

are bumps, (dents), in the passenger side cover from when I had a

rocker come loose. |

Here is a better photo of the 2 dents. |

Oil test: |

68psig |

Oil to every lifter-pushrod-rocker. |

Oil pump drive gear bolt torqued to 22ft-lb and I'm using a

cut-in-half pushrod guide as a washer. |

The LT4 valve cover studs need to be shortened because the Dart

heads are tapped shallow at the valve cover bolt holes. |

I replaced the dented valve cover with another set I had that is

dent free. They are a bit more "used" looking but

they are not dented. |

Here is the motor drained of oil and ready for shipping. |

Another pose. |

|