|

I am very impressed with the block prep. SK smoothed the block

inside and out and enlarged the oil drain back holes.

|

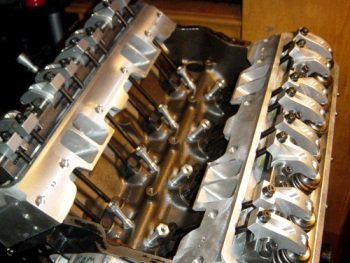

The motor has AFR heads, Jesel shaft rockers and coated JE custom

pistons.

|

The Crower lifters and bushed lifter bore and lifter valley

stands/vents. |

Here I'm taking out all the rod/piston sets to measure rod bearing

clearance. |

All of the rod/piston pairs are out. |

All rod bearing clearances were measured and most were .0025 to

.0027" but a few were .0020" to .0023". I'll

work on that and adjust with different bearings. |

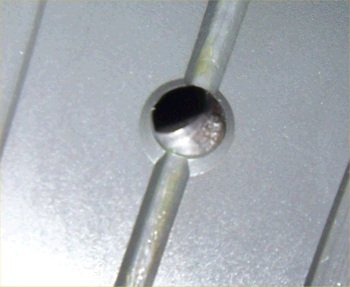

The rear main bearing oil hole never fits well over the LT1 block

oil hole. |

After careful grinding with a Dremel tool there is a bit better

fit.

|

Before taking off all the main caps I checked crank end play and

it's at .006"

With the rear main bottom cap off it's .010" which is a sign

that the thrust cap was not set and torqued so that the rear main

bearing shells share the load evenly. |

All main bearing clearances were checked and it's .0025, .0025,

.0025, .0030, .0030 from #1 to #5 which is right at where Golen

and the other shops I use shoot for. |

Piston ring gap is .030" top and .030" 2nd ring. |

Set crankshaft in place and torqued

main caps. Found that the crank did not spin freely.

It had a slight drag every 180deg. Humm. Well

the block and crankshaft went to Brinkley Auto Machine and he

found that the align hone was off and also the crank was tweaked

about .0015". Scott and I think that was from the Cryo

treatment. As of 6-27-08 crank is in the block and it spins

freely. Final assembly soon. |

Measuring main bearing clearance again. This time using

uncoated Clevite H-series, Standard and .001 under. |

Mains #1, 2, 3 get standard size on top and .001" on bottom.

#4 and #5 get standard/standard. (#1,2,3,4=.0030" and

#5=.0035") |

GM extreme timing set. |

BRE cam. |

Working with dip stick and windage tray. |

This Moroso tray might fit with some tin-snip action. |

Lokar dipstick and Moroso windage tray trimmed to fit. |

This set up will require very careful reading and interpretation

of oil on stick. |

Messaged the corners of the tray. |

Billet Fabrication oil pan. |

Heads on and torqued. |

Jesel rockers all on with Crower lifter pre-load set at 1/2 turn. |

The BF pan fit quite nicely but it is 8.5" deep and my Titan

oil pumps are 8.0". |

So I talked SK into a brand new (custom made to fit around a Titan

gerotor oil pump) Stef's oil pan. |

Remember, if you order one of these pans from Stef's it will not

fit over a Titan oil pump unless you specify that it be made to

the Ellwein Engines design. Stan at Stef's can make one for

you. |

These pans are not easy to fit even with all the custom design

features. I still need to clearance some areas inside the

pan and then I make sure to use Permatex "Right Stuff"

RTV. The pan is bolted down without RTV here check for

interference with the rotating assembly. This is a

non-stroker notch pan by the way and it fits on this 396LT1

stroker pretty well. |